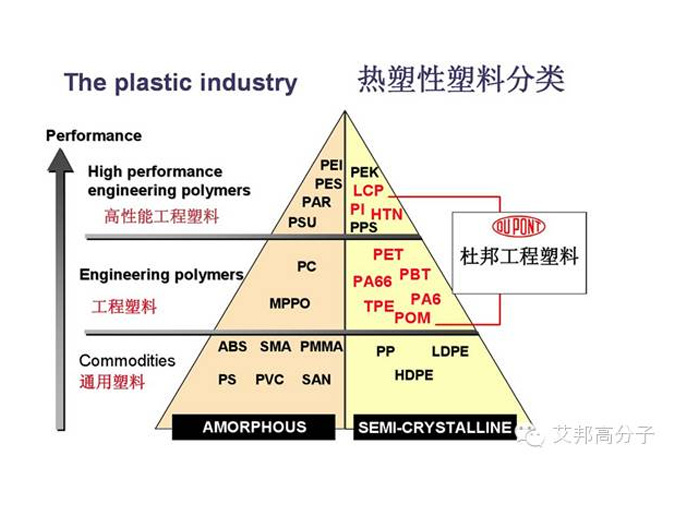

A DuPont map takes you into the world of plastics

Published on:

2023-08-07

Screw disassembly and installation is the customer has been very concerned about the problem, here to teach you how to correctly and effectively replace and install the screw.

Xiaobian believe that many people who have just entered the polymer industry, some English abbreviations for polymers are very large, this edition of Xiaobian will give you benefits, a picture to take you into the plastic kingdom.

Longitudinal - amorphous and semi-crystalline states

Obviously, from the point of view of crystallization characteristics, we can divide thermoplastic into two parts, that is, the left and right part of the triangle, the left plastic represents the amorphous, generally transparent plastic, such as PC cup and PMMA resin lenses in our lives; The plastic on the right represents semi-crystalline plastic, which is generally opaque, for example, we use more PP bottle caps and PE related plastics.

Horizontal - performance use

For the horizontal is more obvious, according to the performance of the plastic use range, it is divided into three parts, respectively, general plastics, engineering plastics and high-performance engineering plastics, of course, the more to the top of the pyramid, the better the performance of the material, the more expensive the price.

The further to the top of the pyramid, whether amorphous or semi-crystalline plastics, their high temperature resistance is better. General general plastics such as PP, PE, PP, ABS and other heat resistant temperature below 100 degrees; Engineering plastics such as PC, PA, PET and other heat resistance temperature below 200 degrees; The heat resistance temperature of high-performance engineering plastics such as PEI, PSU, PEK, etc., is generally between 200 and 300 degrees, and some are even higher.

Hey, this picture also shows DuPont engineering plastic, you can show it off in front of your friends, remember it's the red part.

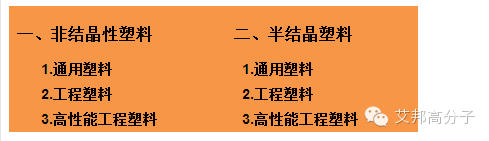

Now let's explain it in two parts:

Catalogue:

一, Non-crystalline plastics

1) General purpose plastics

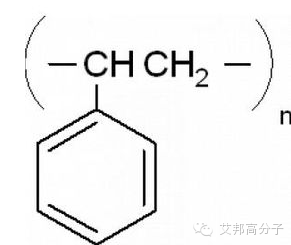

① Polystyrene (PS, Styrene)

PS is a colorless transparent thermoplastic with a glass conversion temperature higher than 100 ° C, so it is often used to make a variety of disposable containers that need to withstand the temperature of boiling water, as well as disposable foam lunch boxes. Reply "PS" to see more

Structural formula:

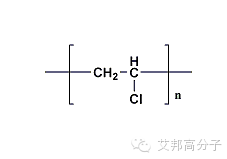

② Polyvinyl chloride (abbreviated PVC)

PVC material is widely used, with good processing performance, low manufacturing cost, corrosion resistance, insulation and other good characteristics, mainly used in the production of: Prewen pvc card; pvc label; pvc wire; pvc curtain; pvc plastic-coated electric welding net; pvc foam board, pvc ceiling, pvc water pipe, pvc kicker, etc., and threading pipe, cable insulation, plastic doors and Windows, plastic bags and so on. PVC products can be seen everywhere in our daily life. PVC is used to make a variety of imitation leather for luggage, sports products, such as basketball, football and rugby. It can also be used to make belts for uniforms and special protective equipment. Reply "PVC" to see more

Structural formula:

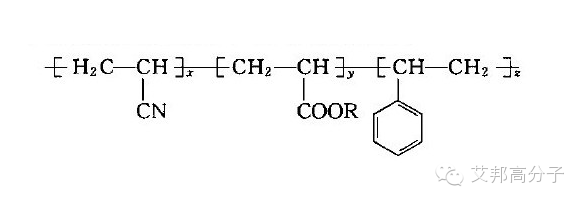

③Acrylonitrile butadiene Styrene copolymers,缩写ABS

ABS is a thermoplastic polymer material structure with high strength, good toughness and easy processing. ABS resin is a terpolymer of acrylonitrile, 1, 3-butadiene and styrene. It can perform normally in the environment of -25 ° C ~60 ° C, and has good formability, and the surface of the processed product is smooth and easy to dye and electroplate. And can be mixed with a variety of resins into blends. Now mainly used in alloys, plastics, and ABS grades. Reply "ABS" to see more

Structural formula:

④ PolymethylMethacrylate (PMMA)

This is an important plastic polymer material developed earlier, with good transparency, chemical stability and weather resistance, easy dyeing, easy processing, beautiful appearance, has a wide range of applications in the construction industry. Plexiglass products can usually be divided into cast plates, extruded plates and molded plastics.

Structural formula:

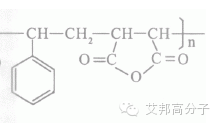

⑤ Styrene-maleic anhydride copolymer (SMA) copolymer

Random copolymer of styrene and maleic anhydride, thermoplastic resin. The latter content of 5% to 30%, good impact resistance, colorless transparent, rigidity and dimensional stability, ability to general chemicals, not resistant to concentrated alkali, ketones and ester solvents. It can be used as automobile instrument panel and interior decoration parts, household appliance parts, etc. Used as adhesive, paper enhancer, protective colloid, etc.

Structural formula:

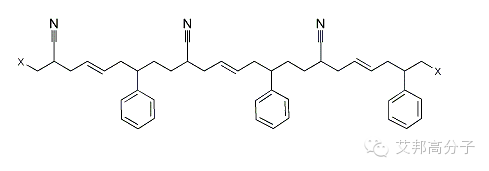

⑥ Acrylonitrile and Styrene copolymer (Styrene-acrylonitrile copolymer, abbreviated SAN/AS)

SAN, also known AS AS, is a polymeric compound made of acrylonitrile and styrene. Generally contains 15%-50% styrene. A solid, transparent yellow to amber needle. It does not change color easily. It is not affected by dilute acid, dilute base, dilute alcohol and gasoline. But soluble in acetone, ethyl acetate, dichloroethylene and so on. Excellent heat resistance and solvent resistance. Used for producing oil-resistant mechanical parts, instrument shells, instrument panels, battery boxes, tractor fuel tanks, battery shells, packaging containers, daily necessities, etc. It can also be drawn into monofilament. However, it is mainly used as a blend for the production of ABS resin.

Structural formula:

2) Engineering plastics

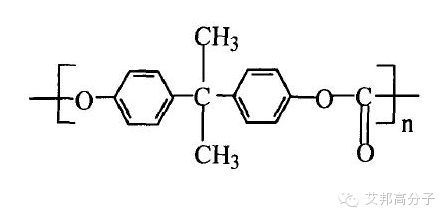

① Polycarbonate (abbreviated PC)

Polycarbonate (PC for short) is a polymer containing carbonate ester group in the molecular chain, according to the structure of the ester group can be divided into aliphatic, aromatic, aliphatic - aromatic and other types. The three major application areas of PC engineering plastics are the glass assembly industry, the automotive industry and the electronics and electrical appliances industry, followed by industrial machinery parts, optical discs, packaging, computers and other office equipment, medical and health care, film, leisure and protective equipment.

Structural formula:

② Polyphenylene Oxide (abbreviated MPPO/PPO)

Polyphenyl ether is easy to process and form, extrusion, injection and molding can be done. It is used in the manufacture of medical devices instead of stainless steel, which can withstand steam disinfection, and is also used in mechanical and electronic parts, insulating materials, etc. Polyphenyl ether and polystyrene blend modifier in the United States trade name Noryl, and can add 20% to 30% glass fiber, carbon fiber and other reinforcement, is a good performance of engineering plastics and insulation materials.

Structural formula:

3) High-performance engineering plastics

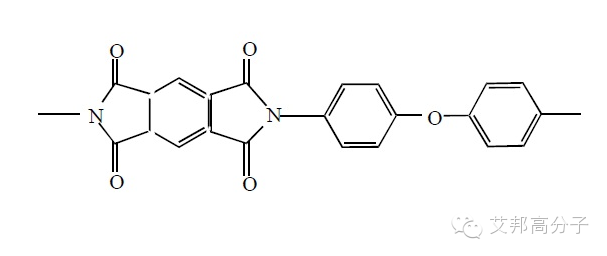

Polyetherimide (PEI)

It has excellent mechanical properties, electrical insulation properties, radiation resistance, high and low temperature resistance and wear resistance, and can be transmitted through microwave. PEI also has good flame retardancy, resistance to chemical reactions and electrical insulation properties. The glass transition temperature is very high, up to 215℃. PEI also has a very low shrinkage rate and good isodirectional mechanical characteristics. Adding glass fiber, carbon fiber or other fillers can achieve the purpose of strengthening modification; It can also be composed of heat-resistant polymer alloys with other engineering plastics, which can be used for a long time at the working temperature of -160 ~ 180 ° C.

Structural formula:

② Polyethersulfone resin (PES)

A thermoplastic polymer material with excellent comprehensive properties developed by ICI in 1972 is one of the few special engineering plastics currently applied. It has excellent heat resistance, physical and mechanical properties, insulation properties, etc., especially with the outstanding advantages of continuous use at high temperatures and the ability to maintain stable performance in the environment of rapid temperature changes, and has been widely used in many fields.

Structural formula:

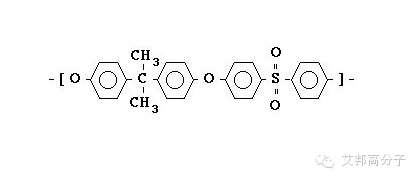

③ Polyarylate (abbreviated PAR)

It is a transparent amorphous thermoplastic engineering plastic with excellent heat resistance, flame retardancy and non-toxicity. It can be directly processed into products by ordinary thermoplastic forming methods. With excellent thermal performance, under the load of 1.86MPA, the thermal deformation temperature is as high as 175 degrees, and the decomposition temperature is 443 degrees. Its mechanical properties are less affected by temperature.

Structural formula:

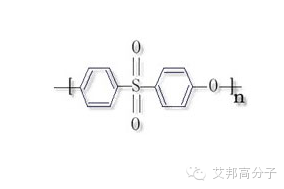

④ Polysulfone (PSU)

PSU (Polysulfone) is a slightly amber amorphous transparent or translucent polymer with good radiation stability, low ionic impurities, and good chemical and hydrolysis resistance. It is a linear thermoplastic engineering plastic, with excellent heat resistance, oxidation resistance, radiation resistance, electrical insulation, outstanding creep resistance and high physical and mechanical properties, excellent chemical corrosion resistance, in addition to strong solvents, concentrated sulfuric acid, nitric acid and other chemical reagents (such as inorganic acid, alkali and salt) stability.

Structural formula:

二、semi-crystalline plastics

1) General purpose plastics

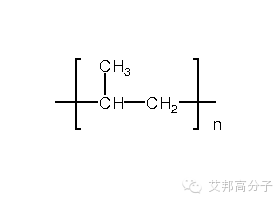

① Polypropylene (Polypropylene, abbreviated PP) was polypropylene.

Commonly known as: folding glue, polypropylene can be divided into isotactic polypropylene, random polypropylene and intertactic polypropylene three configurations. Isotactic polypropylene is easy to form crystalline state, crystallinity of more than 95%, molecular weight between 8-150,000, giving him good heat resistance and solvent resistance; Atactic polypropylene is an amorphous, microbanded viscous ash at room temperature, with low molecular weight, between 3000-10000, irregular structure, lack of cohesion, and few applications. Reply "PP" to see more

Structural formula:

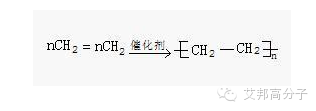

② Polypropylene (Polypropylene, abbreviated PE) was polypropylene.

Polyethylene is a thermoplastic resin produced by polymerization of ethylene. Polyethylene odorless, non-toxic, feel like wax, has excellent low temperature resistance, good chemical stability, resistance to most acid and alkali erosion. Insoluble in general solvents at room temperature, low water absorption, good electrical insulation. The mechanical properties of polyethylene are general, the tensile strength is low, the creep resistance is not good, and the impact resistance is good. Polyethylene can be processed by blow molding, extrusion, injection molding and other methods, and is widely used in the manufacture of thin films, hollow products, fibers and daily necessities.

Structural formula:

2) Engineering plastics

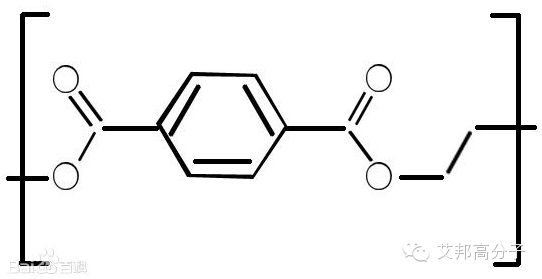

① Polyethylene terephthalate (polyethylene terephthalate, abbreviated PET)

PET is a milky white or light, highly crystalline polymer with a smooth, glassy surface. It has excellent physical and mechanical properties in a wide yellow temperature range, long-term use temperature up to 120℃, excellent insulation, even at high temperatures, its electrical properties are still good, but poor corona resistance, creep resistance, fatigue resistance, friction resistance, dimensional stability are very good.

Structural formula:

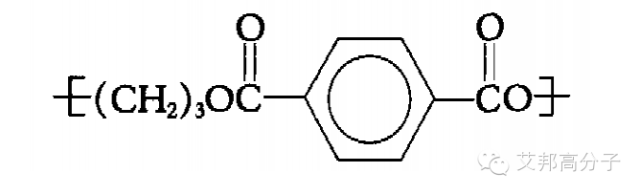

② Polybutylene terephthalate (polybutylene terephthalate, abbreviated PBT)

Polybutylene terephthalate belongs to the polyester series, milky white translucent to opaque, molded polyester resin. Together with PET is collectively known as thermoplastic polyester, or polyester polyester. Evaluate household appliances (food processing blades, vacuum cleaner components, electric fans, hairdryer housings, coffee utensils, etc.), electrical components (switches, motor housings, fuse boxes, computer keyboard keys, etc.), the automotive industry (cellular Windows, side panels, wheel covers, door and window components, etc.).

Structural formula:

③ Polyamide (PA66)

It is a general term for the high content of amide groups in the repeating units of the main chains of macromolecules. Widely used in the manufacture of mechanical, automotive, chemical and electrical equipment parts, such as gear, roller, pulley, roller, pump body impeller, fan blade, high pressure seal, valve seat, gasket, bushing, various components, support frame, wire package inner layer, etc.

Structural formula:

④ Polycaprolactam (PA6)

PA6, also known as conforming 6, is a translucent or opaque milky raw material, with thermoplastic, light weight, good toughness, chemical resistance and good stability and other characteristics, generally used in auto parts, mechanical parts, electronic and electrical products, engineering accessories and other products.

Structural formula:

⑤ Thermo Plastic Elastomer (TPE)

Thermoplastic Elastomer TPE (Thermoplastic Elastomer) is a kind of material with high elasticity, high strength, high resilience of rubber, and has the characteristics of injection molding. It has environmental protection, non-toxic and safe, a wide range of hardness, excellent coloring, soft touch, weather resistance, fatigue resistance and temperature resistance, excellent processing performance, no need to vulcanization, can be recycled to reduce costs, both secondary injection molding, and PP, PE, PC, PS, ABS and other matrix materials coating bonding, can also be molded separately. Reply "TPE" to see more

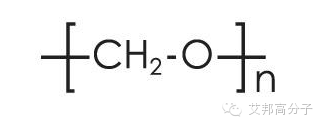

⑥ PolyformalDehyde (POM)

polyformaldehyde is a thermoplastic crystalline polymer. Known as "super steel" or "game steel", also known as polyoxymethylene. The English abbreviation is POM. Generally, the polymer obtained from formaldehyde polymerization has low polymerization degree and is susceptible to pyrolytic polymerization. It can be used as raw material of organic chemical industry, synthetic resin, and also used as drug fumigant.

Structural formula:

3)High performance engineering plastics

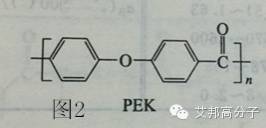

①Polyether ketone(Polyetherketoneketone,Abbreviation PEK)

A polymer whose backbone consists of alternating ether and ketone bonds. The typical polymer is polyaryl ether ketone, a kind of special engineering plastic formed by high temperature condensation of difluorobenzophenone and aromatic diphenol, and can also be condensed by aromatic dihalide and 4,4' -dihydroxybenzophenone to become generally high thermal oxygen stability. High mechanical properties, is a special engineering plastic. Applied to high temperature resistant structural materials, special coatings, wear-resistant materials and electrical insulation materials.

Structural formula:

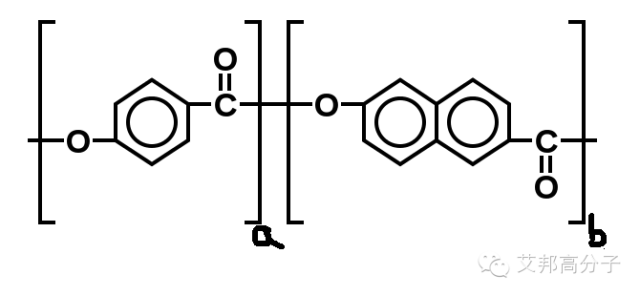

②Liquid crystal polymer(Liquid Crystal Polymer,Abbreviation LCP)

Domestic called liquid crystal polymer, is a new type of polymer material, in a certain state of heating will generally become liquid crystal form, so it is named, its characteristics determine the use of LCP plastic raw materials.

Structural formula:

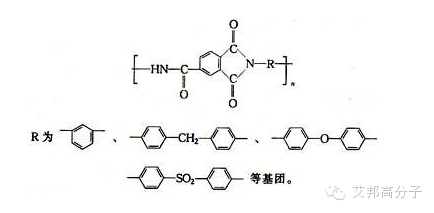

③Polyimide(Polyimide,AbbreviationPI)

As a kind of special engineering material, polyimide has been widely used in aviation, aerospace, microelectronics, nano, liquid crystal, laser and other fields. Recently, the research, development and utilization of polyimide have been listed as one of the most promising engineering plastics in the 21st century. Polyimide, because of its outstanding characteristics in performance and synthesis, whether as a structural material or as a functional material, its huge application prospects have been fully recognized, known as the "problem solver", and that "no polyimide would not have today's microelectronics technology".

Structural formula:

④HTN

A high performance nylon from DuPont, Zytel® HTN high performance polyamide resin aims to reduce weight, increase strength, enhance durability, improve thermal performance, simplify processing, and achieve all of the above in combination. These high performance resins contain specific specifications to maintain high strength and rigidity over a wide temperature range, chemicals and humid environments.

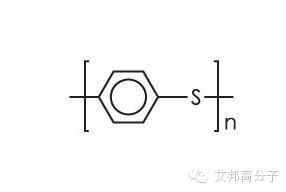

⑤Polyphenylene sulfide(Polyphenylene sulfide,abbreviation PPS)

It is a thermoplastic special engineering plastic with excellent comprehensive properties, and its outstanding characteristics are high temperature resistance, corrosion resistance and superior mechanical properties. PPS is a kind of aromatic polymer containing sulfur. Straight chain PPS is thermoset when crosslinked above 350℃, and branched chain PPS is thermoplastic. PPS was first industrialized by Phillips in 1971, and after the patent expired, Japanese companies began research and development and production. Japanese enterprises are more typical of Toray Company, at this stage, Japan's output has been greater than the United States. Other manufacturers are also concentrated in the United States, Japan and Europe. Reply to "PPS" to see more

Structural formula:

Related News

Related News